Our Electrical Team’s Strengths

Our team of electrical engineers and designers apply their deep knowledge of electrical codes and fundamentals coupled with their hands-on experience to design and implement cost-effective, intuitive, robust solutions for electrical challenges. From a short circuit/fault current analysis to an arc flash study, electrical gear upgrades to entire industrial plant electrical power and motor control systems, we have the skill set, knowledge base, and experience to fill your electrical needs, large or small.

Whether your project involves a Retrofit or New Construction, Hazardous Classification or Non-Classified, 15,000 Volts to 110, we offer the following services to solve your challenges.

Electrical Engineering Services

- Complete Electrical Project Engineering, Estimating and Scheduling for new installations and/or modifications of existing systems.

- Field survey of existing systems with recommendations of improvement.

- Providing field engineers and technicians for monitoring new installations and for checkout and start-up

- Single Line Electrical Diagrams

- Main Substation Planning

- Electrical Power Distribution Systems

- Motor Control Center Layouts

- Branch Circuit Layouts & Panel Scheduling

- Fault Current, and Coordination Studies

- Arc flash studies and mitigation

- Motor Elementaries

- Indoor/Outdoor Lighting

- Electrical Floor Plan Layouts

- Fire Protection & Security Systems

- Electrical Check-out & Start-up

- System Trouble Shooting

- Existing System Documentation

- Electrical Gear and Installation Services Procurement Support

- Feasibility Studies

- Cost Estimating

Ready to Get Started?

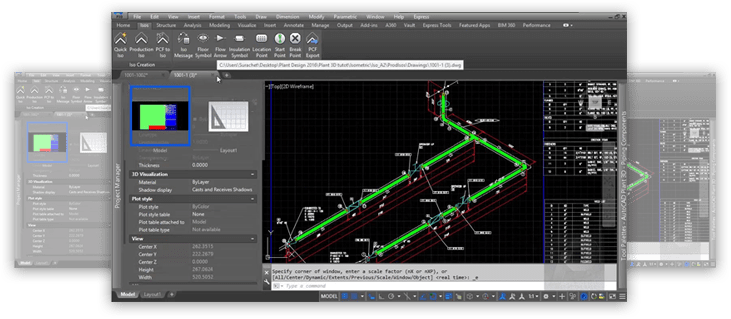

Technology/Software Tools We Use

- SKM Power Tools

- Easy Power

- Revit 3D

- AutoCAD Electrical

- Dranetz 4100 Power platform

- ETAP – ELECTRICAL POWER SYSTEM ANALYSIS

Our Electrical Experience

By the Numbers

Our Electrical Engineers and Designers have a combined total of 123 years of experience and an average of 21 years of experience.

-

160,000+HP of Motors -

3,500+Motors -

100+Substation Transformers

Featured Electrical Engineering Projects

- Type of FacilityCorn Wet Mill

- ServiceDetailed Engineering

Expanding Food Starch Production

A company needing to expand starch production capacity at a corn wet mill enlisted AMG’s expertise for a project with a capital value in excess of $60,000,000. AMG contributed detailed engineering and design services for two areas housing flash dryers and packing machines.

- Type of FacilityFermentation & Extraction Facility

- ServiceDesign-Build Services

Fermentation Expansion Design-Build

An algae fermentation facility in Kentucky utilized AMG’s consulting services to provide complete design-build services for expansions.

The project involved many complex systems including: chiller systems, compressed air, condensate, control system SCADA/HMI, cooling towers, electrical distribution, fermentation, filtration, steam systems, sterilization and pasteurization systems.

- Type of FacilityEnzyme Plant

- ServiceEngineering Procurement & Construction Management (EPCM)

EPCM for Enzyme-Blending Plant

AMG provided EPCM services to construct an enzyme blending facility. The project involved receiving different enzyme varieties in various containers sizes ranging from ISO containers (Conex) to totes, and blending them to produce specialty enzyme cocktails for use in multiple agricultural processing industries. Various systems were involved including truck receiving, warehousing, automated overhead cranes, ISO container unloading, pumping systems, CIP systems, enzymes testing laboratory, deep foundations, power distribution, PEMBs, etc..

In addition to providing procurement support and construction management, AMG provided complete detailed engineering services encompassing process, mechanical, piping, electrical, control systems, and structural engineering.

- Type of FacilityCorn Wet Mill

- ServiceDetailed Engineering

Rotary Feed Dryer and RTO

AMG provided detailed engineering services for upgrades at a corn wet mill in Tennessee. The project involved replacing an existing gas-fired rotary feed dryer with a new rotary dryer as well as adding a new regenerative thermal oxidizer (RTO).

- Alabama

- Arkansas

- Arizona

- Colorado

- Florida

- Georgia

- Iowa

- Illinois

- Indiana

- Kansas

- Kentucky

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Missouri

- Mississippi

- Montana

- Nebraska

- North Carolina

- Ohio

- Pennsylvania

- South Carolina

- Tennessee

- Texas

- Virginia

- Wisconsin

- West Virginia

- Mexico

- Saskatchewan

- Ontario

Featured Content

Do you have a project that you need help with?

With a just a few key pieces of information we can asses whether we can be of assistance in solving your problem. Please fill out the following boxes and hit the Submit button and we’ll be contact you to discuss how AMG can help.